SECS/GEM

(Semiconductor Equipment Communication Standard/Generic Equipment Model)

MetroSemi specializes in tool automation, bringing over two decades of dedicated service to deliver advanced SECS/GEM and automation solutions to fabs and equipment builders. We consistently refine our tools, elevating their capabilities and ensuring user-friendly interfaces. Our commitment is to empower you to focus on problem-solving, liberated from the limitations of outdated and cumbersome tools.

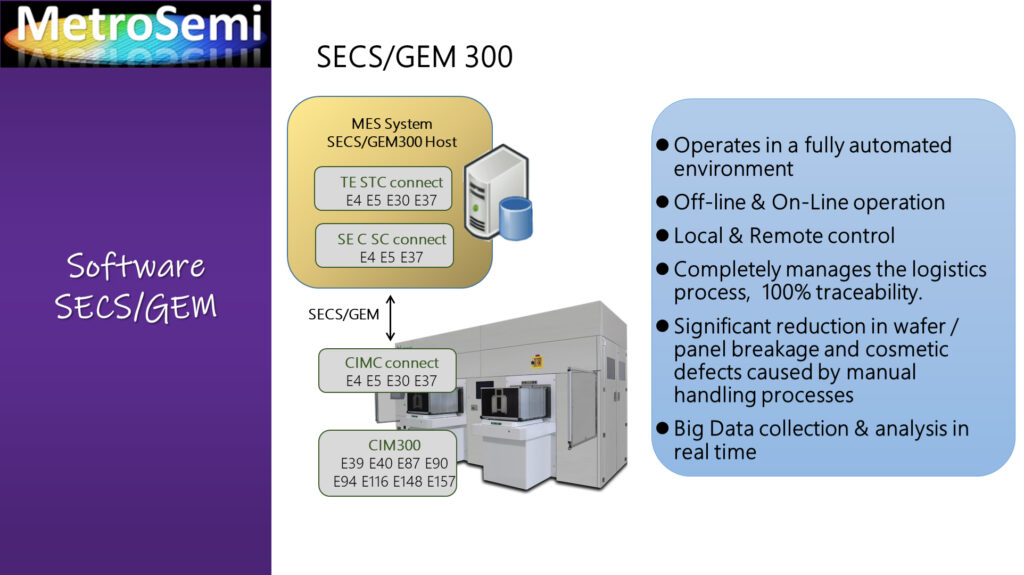

SECS/GEM (Semiconductor Equipment Communication Standard/Generic Equipment Model) is a communication protocol widely used in the semiconductor manufacturing industry to facilitate communication between manufacturing equipment and host systems, such as Manufacturing Execution Systems (MES) or Supervisory Control and Data Acquisition (SCADA) systems.

SECS/GEM automation software refers to software applications that implement the SECS/GEM protocol for automation purposes. This software enables seamless communication and data exchange between different types of semiconductor manufacturing equipment and the overall manufacturing control system.

Key features of SECS/GEM automation software may include:

Communication Protocols: Implementation of SECS/GEM protocol for communication between equipment and host systems.

Data Collection and Reporting: Gathering and reporting of data from manufacturing equipment to the higher-level control systems, facilitating real-time monitoring and analysis.

Equipment Control: Enabling remote control and monitoring of manufacturing equipment through the SECS/GEM protocol.

Alarm Handling: Managing and communicating equipment alarms to the host system for prompt response and issue resolution.

Recipe Management: Handling and executing recipes for different manufacturing processes, ensuring consistency and repeatability.

State Management: Monitoring and reporting the current state of the equipment, allowing the host system to track the progress of manufacturing processes.

SECS Message Handling: Parsing and generating SECS messages in accordance with the SECS/GEM standard.

Error Handling: Managing errors and exceptions to maintain the reliability and stability of the manufacturing process.

SECS/GEM automation software plays a crucial role in improving efficiency, reducing errors, and enhancing the overall automation capabilities of semiconductor manufacturing facilities. It helps to standardize communication between equipment from different manufacturers, promoting interoperability and compatibility in the highly complex semiconductor manufacturing environment.