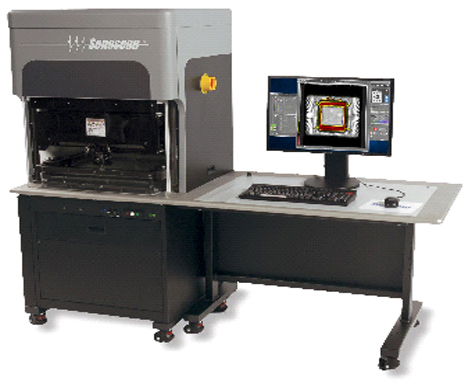

D9650 C-SAM®

The Standard for Acoustic Microscopes.

Maximum Flexibility for Detailed Acoustic Inspections

Features and Benefits

- Discover defects first with our latest, easiest and most intuitive user interface Sonolytics 2.

- Save time by collecting up to 100 images in one scan.

- Compatibility with existing networks using the latest operating system Windows® 10.

- Easy-access scanning area makes loading and unloading simple.

- Optional features include water recirculation, heater, non- immersion WaterFall and Digital Image Analysis.

The D9650 is the modern Acoustic Microscope standard that delivers the same unmatched accuracy and robustness as its previous generation, plus an improved electronics and software platform by incorporating PolyGate technology and Sonolytics 2. The D9650 is ideal for failure analysis, process development, material characterization and low-volume production environments.

Whether your needs are for failure analysis, process development, material characterization, low-volume production or other lab inspections, the D9650 delivers unmatched capabilities. Operating in both reflection and/or transmission modes, the D9650 provides a level of accuracy and robustness that sets the modern standard for AM imaging.

In addition to being packed with leading Sonoscan innovations, the D9650 was carefully designed with the user in mind. Its ergonomic features make it comfortable and convenient to use. Its advanced applications Sonolytics 2 software and new intuitive operator interface menus help maximize results, while saving operator time. The D9650 is truly the new generation C-SAM, delivering a package of technology, ergonomics, and advanced Sonoscan-developed features that cannot be found anywhere else.

SONOSCAN C-SAM® D9650 Specifications

Inspection Modes

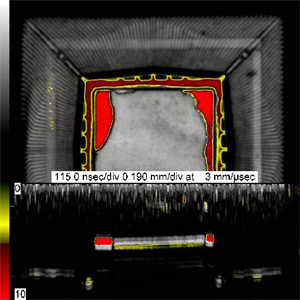

Simultaneously Capture 100 depths of interest (gates) with independent gains, color maps and waveform analysis with PolyGate.

Time Domain Imaging TDI includes:

- A-Scan, displays the transducer signal.

- B-Scan, provides a cross-sectional image.

- C-Scan, is a two-dimension plane image.

- Bulk Scan, reveals defects within a material.

- MultiScan, simultaneously gathers images at different levels.

- Surface Scan, shows defects at the surface level.

- Interface Scan, highlights changes between two materials.

- Loss of Back Echo (LoBE), create shadows from above defects.

- Nordson SONOSCAN exclusive Q-BAM a focused cross-sectional view of a sample.

- 3D TOF, uses time-based analysis to create a depth or thickness image.

- Optional THRU-Scan™ displays material continuity and delamination or voids.

- Optional Simultaneous THRU-scan and Reflection STaR, saves time by collecting THRUScan And any Time Domain Images At the same time.

Waveform analysis modes:

- Amplitude measures peak-to-peak signal and polarity.

- Integration Mode allows diminished signals to stand out.

- Profile analyzes distance from front surface to interface of interest.

- Time Difference evaluates distance between two interfaces.

- Acoustic Surface Flatness ASF measures surface warpage. Patent US 8,794,072 B2

- Polarity (i.e., phase) and amplitude information with Acoustic Impedance Polarity Detector Patent US 4,866,986

Advance triggering tools:

- Positive, Negative and ± crossing.

- Automatic Front Interface Echo FIE-mode, saves time by automatically capturing first reflection interface.

- Compensation for Internal thickness variations using Dynamic Trigger.

- For seeing the entire A-Scan signal Main Bang mode allows advance users to utilize advance Trigger functions Gated Trigger For more challenging applications.

AutoScan provides automatic inspection and analysis of an arrangement of parts on trays via preprogrammed instructions for location, focus, scan size, and analysis.

Quickly discover the best setting with Multi-FocusPolyGate provides an array of images to select.

System

Mechanical

- Scan Area 314 mm x 314 mm

- X-Y accuracy ±0.5 µm

- Motors X-Axis High speed linear- Y-Axis stepper, Z-Axis stepper

Electrical

- Pulser / Receiver Optimized for Transducer- 5 MHz to 230 MHz, 95 dB Gain 0.5 dB steps

- Digitizer- 1 GSPS at 8 bits LSNB 1

- Digital Gating 1 ns to 10,000 ns

Operating System Windows 10® Sonolytics 2

Facility Requirements

Universal Voltage- 90 VAC to 250 VAC 50/60 Hz, single phase, 15-amp circuit 120 VAC

Dimensions

- Width 1,892 mm

- Depth 737 mm

- Height 1588 mm

- Weight Minimum 420 kg, Maximum 500 kg

Water and Drain

- Water Fill ½” ID hose

- Fill Pressure 150 kPa ± 50 kPa

- Water Drain ½” ID hose

- Table Drain ½” ID hose

Optional Features and Equipment

- Water Management automatically fills, drains, recirculates, filter functions and provides overflow protection.

- WaterFall for non-immersion scanning.

- Heated Water for decreasing high frequency attenuation of water.

- Digital Image Analysis (DIA) for quantifying acoustic data, includes area fraction analysis (including Mil-Std-883, Method 2030), image enhancement, histogram, FFT, multi-area analysis, and thickness calculations.

- Virtual Rescanning Module (VRM) stores 100% of A-Scan data to allow further analysis of a part no longer available.

- Universal Wafer Fixture.

- Acoustic Impedance Measurement Module (AIMM) for measurement of the acoustic impedance of materials.

- Thickness Measurement Module.

- Spectral Analysis Module.

- THRU-Scan arm

- STaR