FSM 128 Film Stress & Wafer Bow Measurement System

Introduction

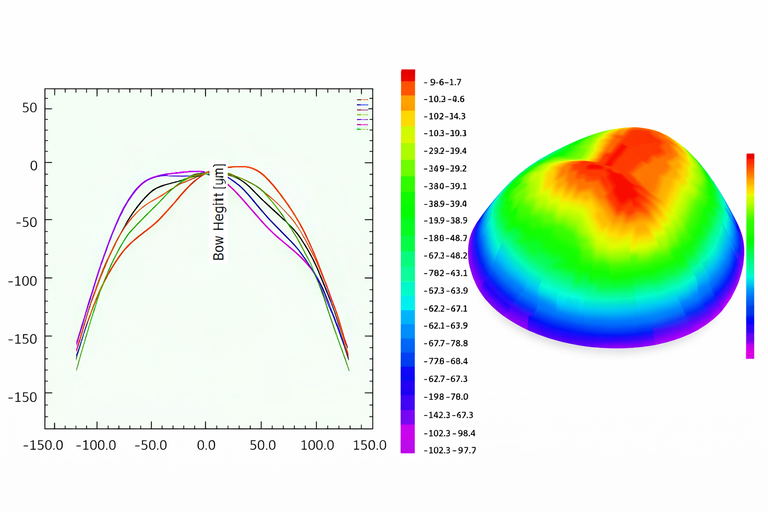

The FSM 128 is an advanced system for precise wafer stress, curvature, and bow measurement. Utilizing a non-contact technique, it ensures accuracy and reliability. Available in Film Stress & Wafer Bow Measurement System, it supports wafers up to 300mm, providing 2D/3D stress mapping with intuitive operation.

Specifications

- Film Stress Range: 1 MPa to 1.4 GPa (for Si wafers with ≥1µm bow/curvature change)

- Bow Sensitivity: Detects 1-micron height changes (P-doped Si)

- Scan Range: 3mm edge exclusion

- Mapping: 32 scan lines (6 recommended) with 40 data points/mm

- Bow Measurement: Measures bow heights up to 2000µm

- Advanced Optics: Patented dual laser switching for accuracy

- Software: Windows 7–11 compatibility, data export to Excel™, JPEG maps

- Operating Conditions: Ambient temperature

- Measurement Method: Non-contact laser scanning

- Wafer Compatibility:

- FSM 128NT: 50mm to 200mm

- FSM 128L: 50mm to 300mm

- Wafer thickness: <5mm

- Scanning: High-precision single scan and programmable multiple diametric scans for 2D/3D mapping

- Repeatability: 1% (1 sigma) on a 20m curvature mirror standard

- Accuracy: <2.5% on a 20m radius curvature mirror

- Laser Class: Class 1

Data and Connectivity

- Export results to Excel™ or JPEG.

System Requirements

- Computer: Intel Core i5 or later, 2GB RAM, 1TB hard drive, 4 USB ports, 2 Ethernet ports.

Dimensions & Weight

- FSM 128NT: 14″ (W) x 20″ (D) x 16″ (H), 55 lbs

- FSM 128L: 14″ (W) x 28″ (D) x 16″ (H), 60 lbs

Power Requirements

- 110V/220V; 20A

Notes

- Wafer bow is the deviation of the center point of the wafer’s front surface when supported on a 3-point system.

Repeatability and accuracy depend on film type, thickness, and substrate.

Semiconductor, Optoelectronics & FPD Application

FSM 128C2C Automated Film Stress & Wafer Bow Measurement System

Introduction

The FSM 128C2C series is a fully automated system designed for stringent production environments, including next-generation devices in 300mm fabs, III-V, and MEMS industries. It offers robotic cassette handling and supports wafers ranging from 150mm to 300mm. Configurations include open cassette, SMIF, and mini-environment modules.

Specifications

- Film Stress Range: 1 MPa to 1.4 GPa (Si wafers with ≥1µm bow/curvature change)

- Bow Sensitivity: Detects 1-micron changes (P-doped Si)

- Scan Range: 3mm edge exclusion

- Mapping: 32 scan lines (6 recommended) with 40 data points/mm

- Bow Measurement: Measures up to 2000µm bow heights

- Advanced Optics: Patented dual laser switching

- Software: Windows 7–11, export to Excel™ or JPEG

- Operating Conditions: Ambient temperature

- Measurement Method: Non-contact laser scanning

- Scanning: High-precision single scan and programmable multiple diametric scans for 2D/3D mapping

- Repeatability: 1% (1 sigma) on 20m curvature mirror

- Accuracy: <2.5% on 20m radius curvature mirror

- Laser Class: Class 1

- Wafer Compatibility:

- FSM 128C2C: 150mm to 200mm

- FSM 128C2G-SMIF: Mini-environment option

- FSM 128L C2C: 300mm open cassette

- FSM 128L C2C (SF/DF): 300mm with single or dual FOUP configurations

- Wafer thickness: <5mm

Data and Connectivity

- Export results to Excel™ or JPEG.

- Optional accessories: Wafer slot mappers, cassette ID readers, SECS/GEM communication.

System Requirements

- Computer: Intel Core i5 or later, 2GB RAM, 1TB hard drive, 4 USB ports, 2 Ethernet ports.

Dimensions & Weight

- FSM 128C2C: 38″ (W) x 45″ (D) x 75″ (H), 850 lbs

- FSM 128L C2C: 41″ (W) x 57″ (D) x 75″ (H), 1,000 lbs

- FSM 128L C2C (DF): 58″ (W) x 68″ (D) x 75″ (H), 1,210 lbs

Power Requirements

- 110V/220V; 20A