BAWL-12 Wafer Inspection System

Precision. Efficiency. Reliability.

The BAWL-12 Wafer Inspection System is your ultimate solution for advanced semiconductor wafer inspection. With fully automated wafer handling, high-definition optical imaging, and cutting-edge analysis capabilities, the BAWL-12 series sets a new benchmark in wafer defect detection and process optimization.

Key Features

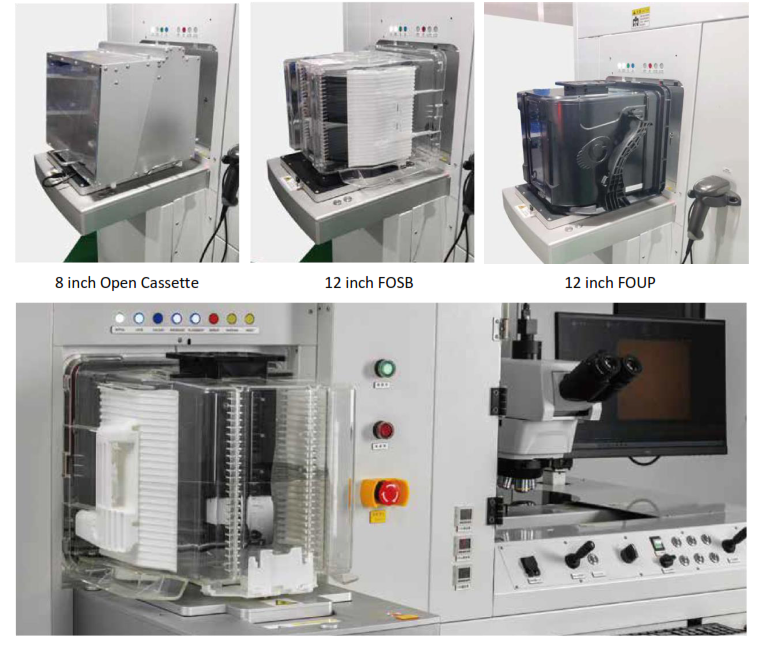

- EFEM System: Smart Wafer Handling

- Automated loading and unloading with precision mechanical arms.

- Compatible with FOUP, FOSB, Smif Pod, and Open Cassettes.

- Advanced barcode scanning and RFID for seamless wafer identification.

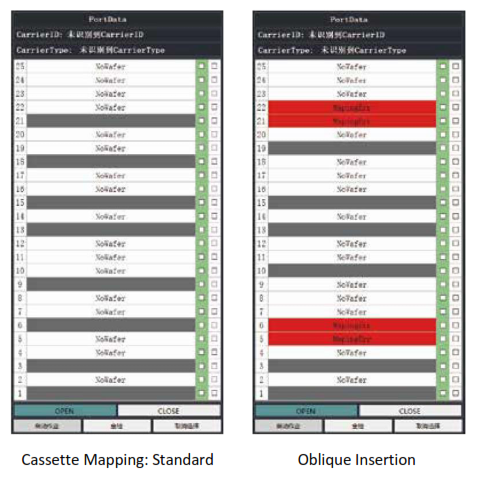

- High-Precision Mapping

- Layer-by-layer scanning for accurate wafer position tracking.

- Detects tilted or misaligned wafers with 100% accuracy.

- Instant alarms for abnormal conditions.

- Non-Contact Wafer Pre-Alignment

- Optical system for precise center and notch/flat location.

- Efficient, automated mechanism for fast, accurate positioning.

- Supports various materials: Si, SiC, EMC, Glass, and more.

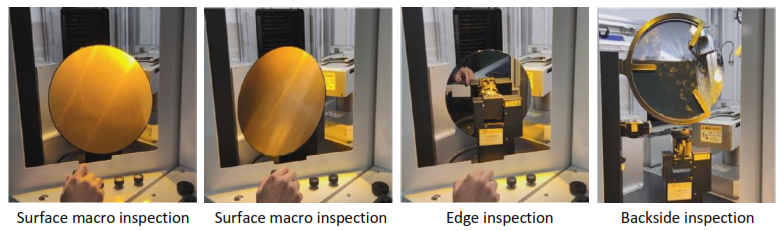

- 360° Macro Inspection

- Full-surface inspection including front, back, and edges.

- Multi-angle viewing via a responsive control lever.

- Customizable LED lighting options: white, yellow, and green.

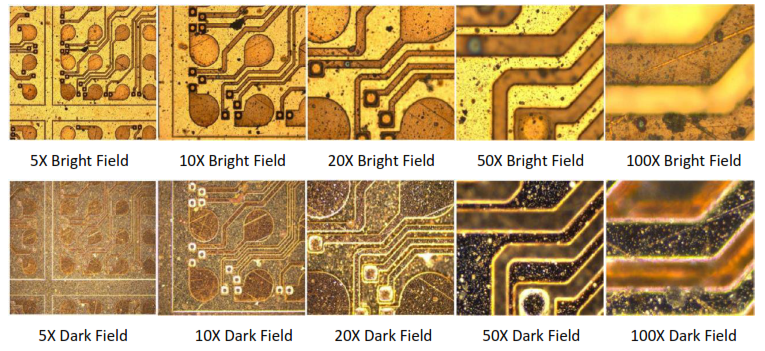

- Ultra-Wide Micro Inspection

- 25mm ultra-wide field of view for detailed imaging.

- High-resolution imaging with polarization and DIC contrast.

- Electric Precision Control

- Electrically controlled objective and diaphragm for optimal accuracy.

- Front-panel controls for ergonomic operation.

- APO Objectives with Long Working Distance

- High-transmittance lenses with superior color correction.

- Non-destructive testing for multiple observation modes (bright field, dark field, polarization, DIC).

- Advanced Image Analysis Software

- Automatic image stitching, depth fusion, and 3D measurement.

- Features auto-focus, particle counting, and real-time visualization.

- Compatible with 64-bit Windows systems.

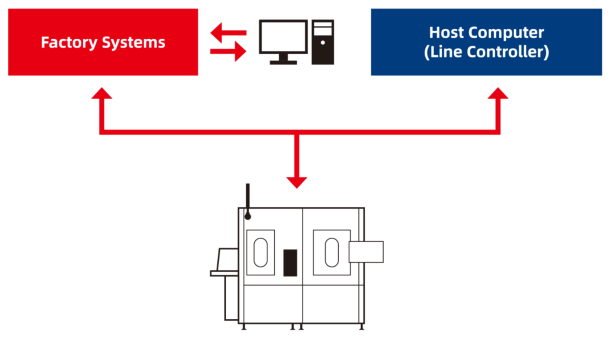

- SECS/GEM Data Communication

- Seamless integration with MES systems for real-time monitoring.

- Wafer OCR for process tracking with unique wafer IDs.

- Power-outage protection ensures data integrity.

- Reliable & Safe Design

- High operational stability and transmission rates.

- Built-in UPS, vacuum holding system, and safety interlocks.

- Complies with SEMI industry standards.

Technical Performance

Parameter | Specification |

Operating Time | >95% |

Chip Rate | 1/100000 |

Maintenance Time | ≤4 hours |

Mean Time Between Errors | ≥240 hours |

System Specifications

Feature | BAWL-12 MS | BAWL-12 AS | BAWL-12 RAS |

Wafer Size | 200mm/300mm | 200mm/300mm | 200mm/300mm |

Wafer Thickness | 250-1000um | 250-1000um | 300-1000um |

Loadport | 1 | 1 or 2 | 1 or 2 |

Wafer Pre-Alignment | Non-contact | Non-contact | Non-contact |

Macro Inspection | ✓ | ✓ | ✓ |

Micro Inspection | ✓ | ✓ | ✓ |

Image Analysis Software | Optional | Optional | ✓ |

SECS/GEM Protocol | Optional | Optional | ✓ |

Wafer Review System | – | Optional | ✓ |

Power Requirements:

- 220V, 50Hz, 16A (MS/AS) | 220V, 50Hz, 32A (RAS)

- CDA: 0.4–0.6 MPa | VAC: -70 to -90 kPa

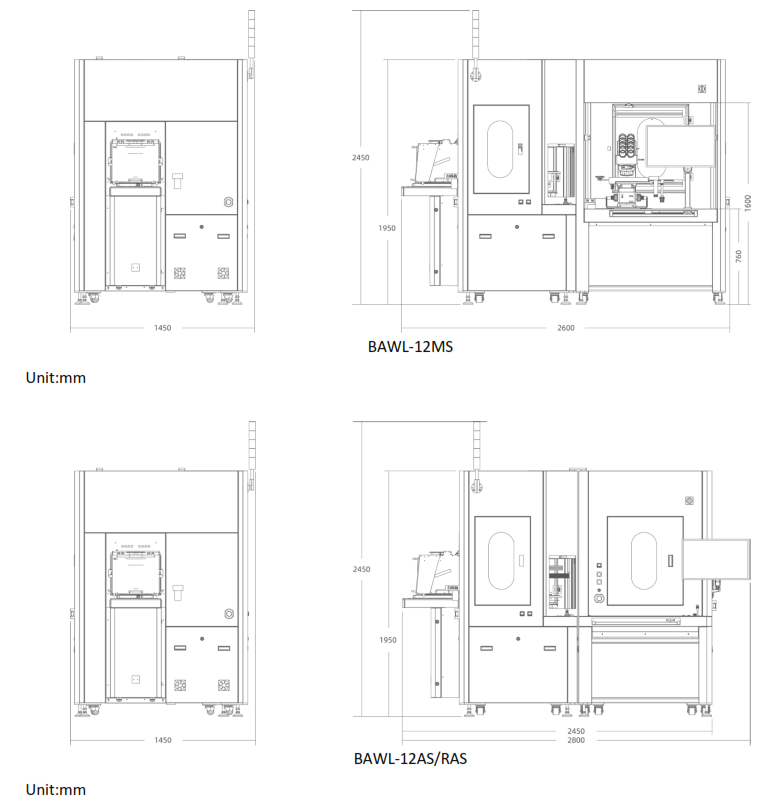

Dimensions:

- 1-Port: 2400mm (W) × 1400mm (D) × 2350mm (H)

- 2-Port: 2400mm (W) × 2050mm (D) × 2350mm (H)

Additional Features:

- High-eyepoint wide-field eyepiece with micrometer.

- Adjustable trinocular head (5–35°) for user comfort.

- Manual or automatic focusing with real-time adjustments.

- Optional accessories: filters, polarizers, DIC kits, and professional inspection software.

Dimension

Why Choose the BAWL-12 Series?

- High Accuracy: Non-contact optical precision for reliable results.

- Enhanced Productivity: Automated processes reduce manual workload.

- Versatile Compatibility: Supports various wafer types and materials.

- Future-Ready Design: Scalable options to meet evolving industry demands.

BAWL-12: Precision You Can See, Performance You Can Trust.